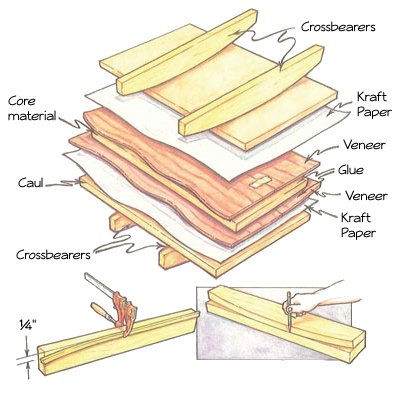

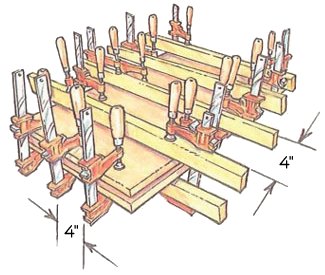

❈ How to Make a Shop-Made Veneer Press If you don't own a veneer press to make veneering easy, build the one shown here. The technique involves the use of two plywood cauls and some wooden crossbearers that have a bow shaped profile along one edge. If you don't own a veneer press to make veneering easy, build the one shown here. The technique involves the use of two plywood cauls and some wooden crossbearers that have a bow shaped profile along one edge.Make the cauls by cutting two pieces of 3/4" plywood slightly larger than the outside dimensions of the veneer - they will serve as the top and bottom of a sandwich. Next, lay a sheet of Kraft paper on the bottom caul (don't glue anything together yet), followed in sequence by the ⅛" Spanish cedar, ¼" core material, the crotch veneer, more Kraft paper and, finally, the second caul. Make the crossbearers next, using the method described in Veneering Wide Panels. You're now ready to dissassemble the sandwich and apply standard yellow woodworking glue to all the relevant surfaces. To get an even coating, try a notched trowel. With the glue applied, work quickly and reassemble the sandwich.  Set the crossbearers in place, beginning at the middle and working toward the ends, clamping a pair every four inches across the width of the press. Set the crossbearers in place, beginning at the middle and working toward the ends, clamping a pair every four inches across the width of the press.

Follow up by setting clamps all around the perimeter, as shown. You'll know that you've applied enough pressure when you can see a bead of glue all the way around the edges. |

|

|

📌 Content © Rockler.com ~ The products on this page are available at Rockler.com.